new stackup generator Controlled Impedance

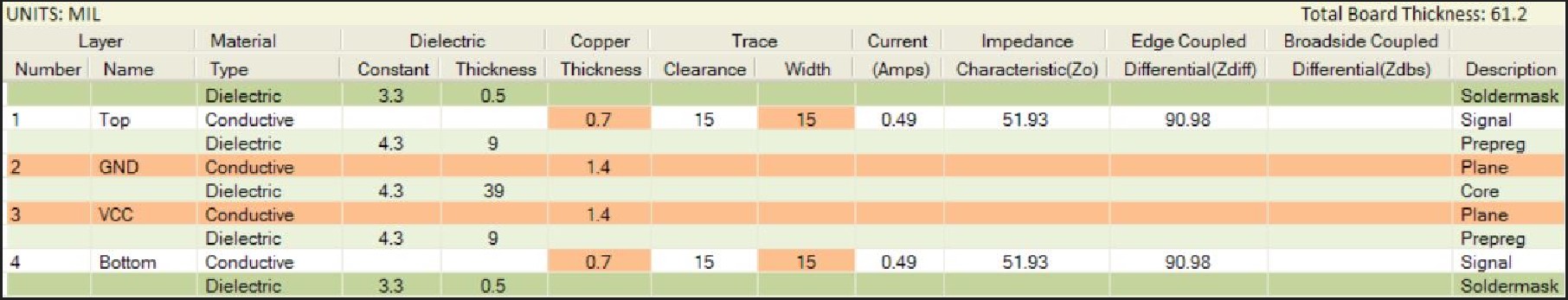

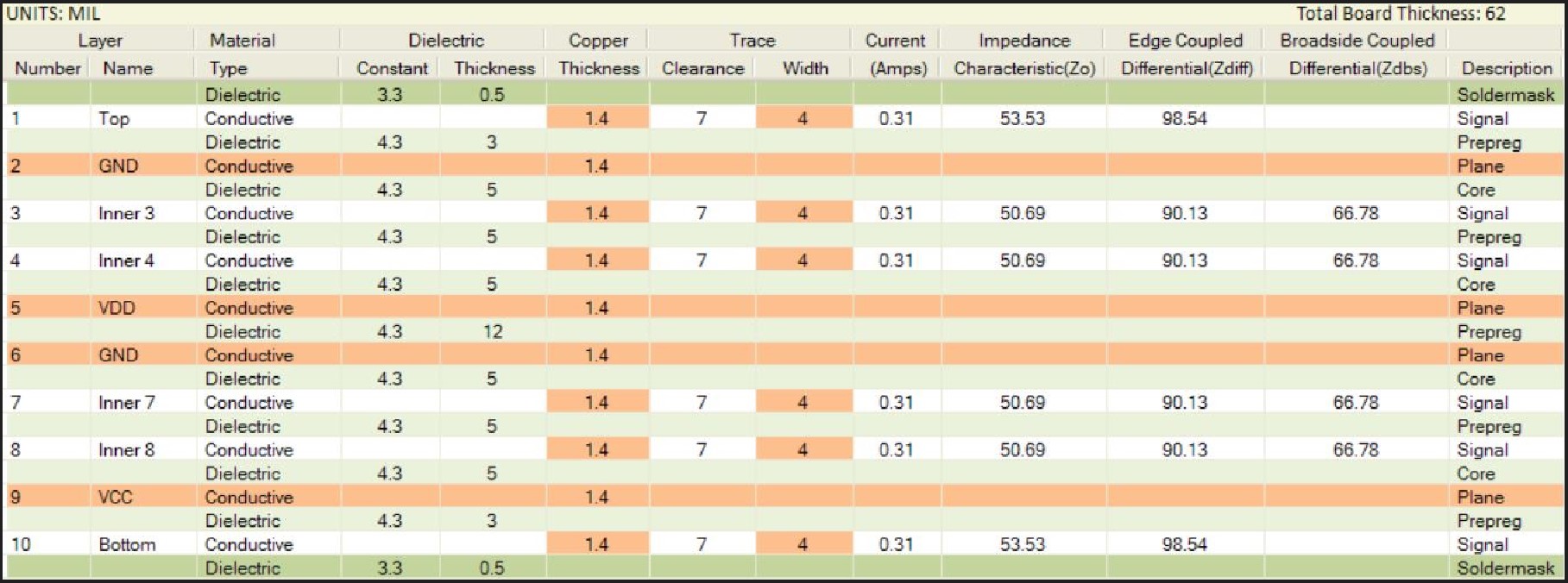

The signals that require these properties are "controlled" by material selection, copper thickness, trace width, spacing (in the case of differential impedance), copper thickness, and in most cases the dielectric distance from the reference layer or plane, among others.

Our customers can choose for AQC to follow the stackup exactly and then no measurements are needed, the calculations are then already done by the customer and the build-up to be followed is specified by the customer himself. Alternatively, the impedance does need to be measured. In that case, our production sites will recalculate the impedance values and provide feedback for verification if required. In many cases, the track width or spacing will be slightly adjusted to achieve the requested impedance. An adjustment of the stackup is then also a possibility. This will then be submitted to the customer for verification.

If, for example, the customer is still in a development process, AQC can assist in determining the correct stackup and the associated calculations to achieve the requested impedances. This can be done in cooperation with the intended production location, because they know exactly which practical variables of their production process influence the requested impedances, such as base copper, etch factor and final thickness between the layers after pressing, in the case of a multilayer. Indeed, this can vary quite a lot between production sites.

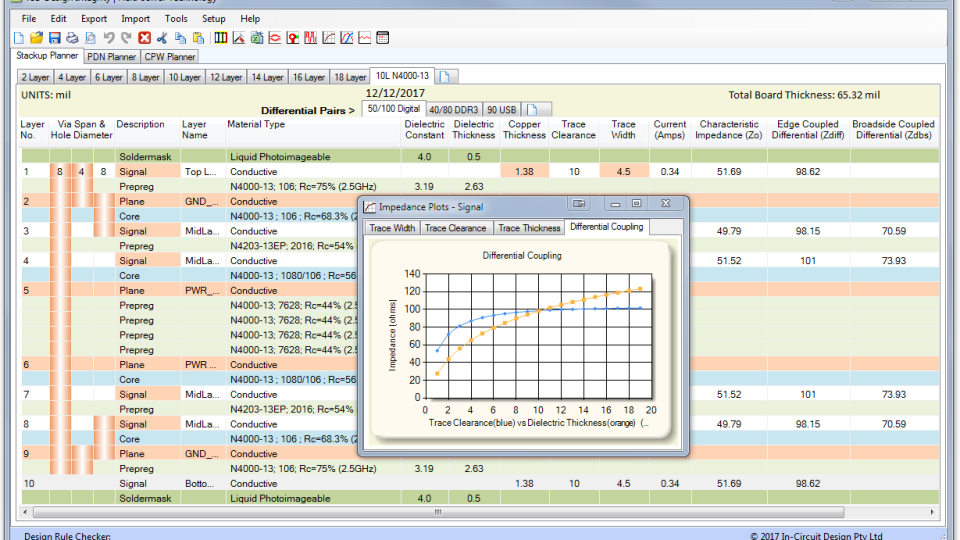

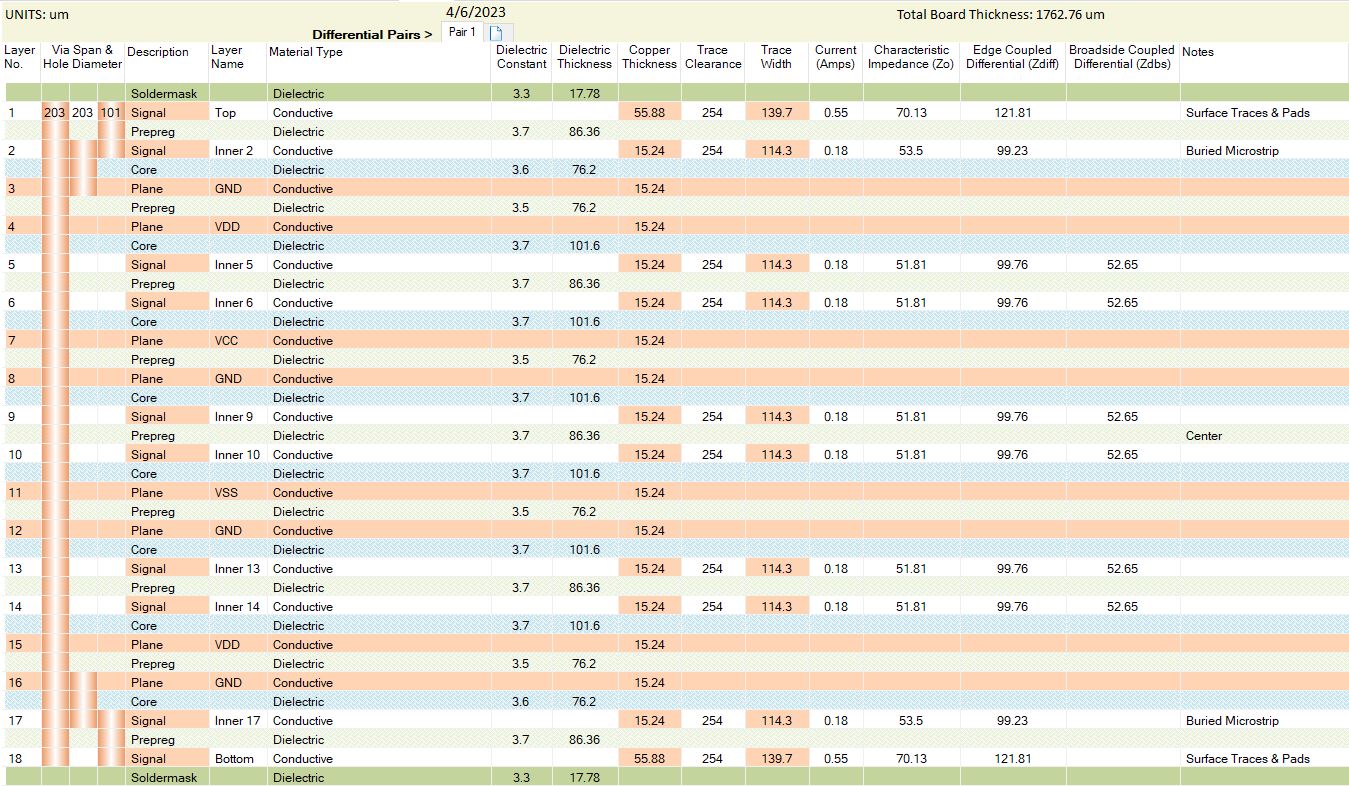

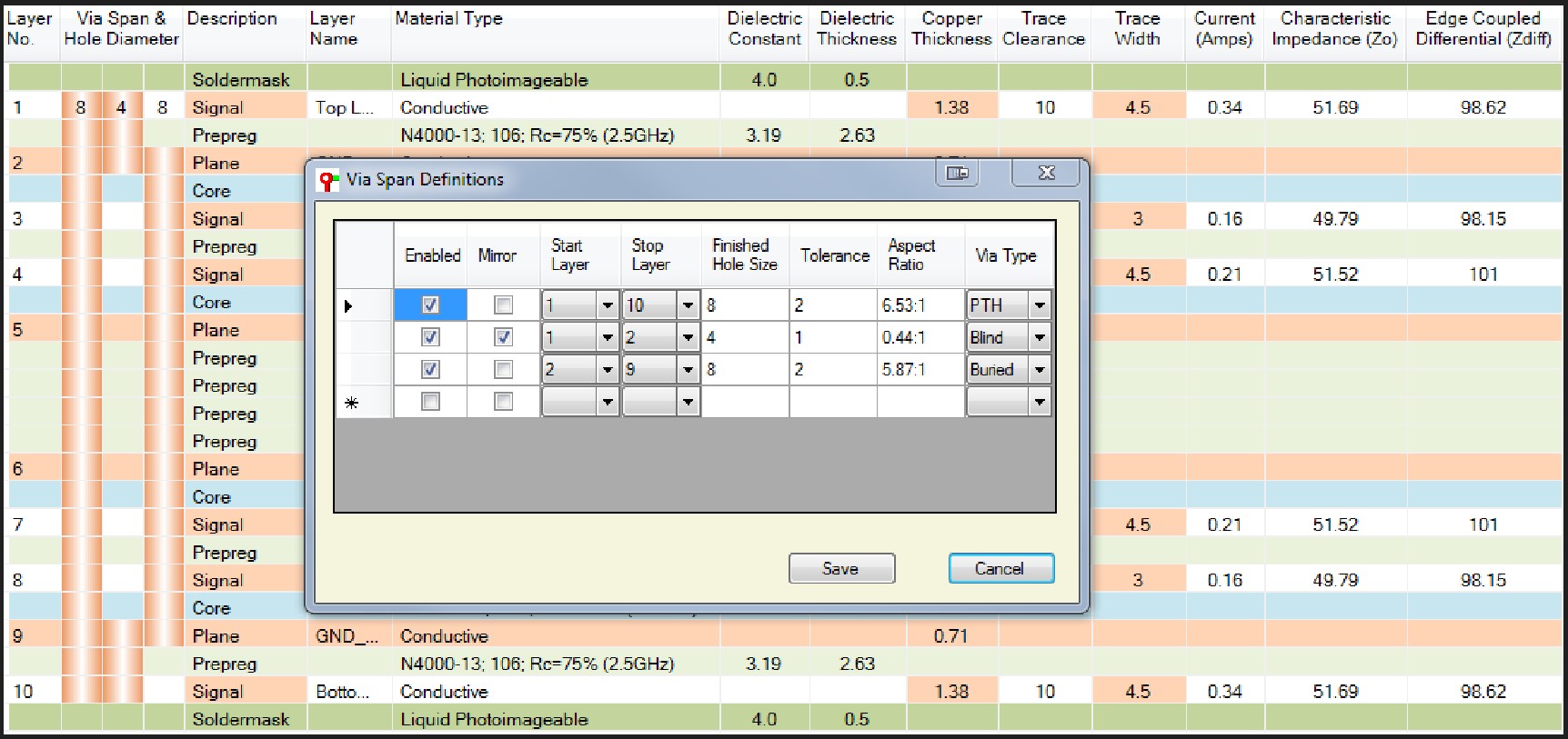

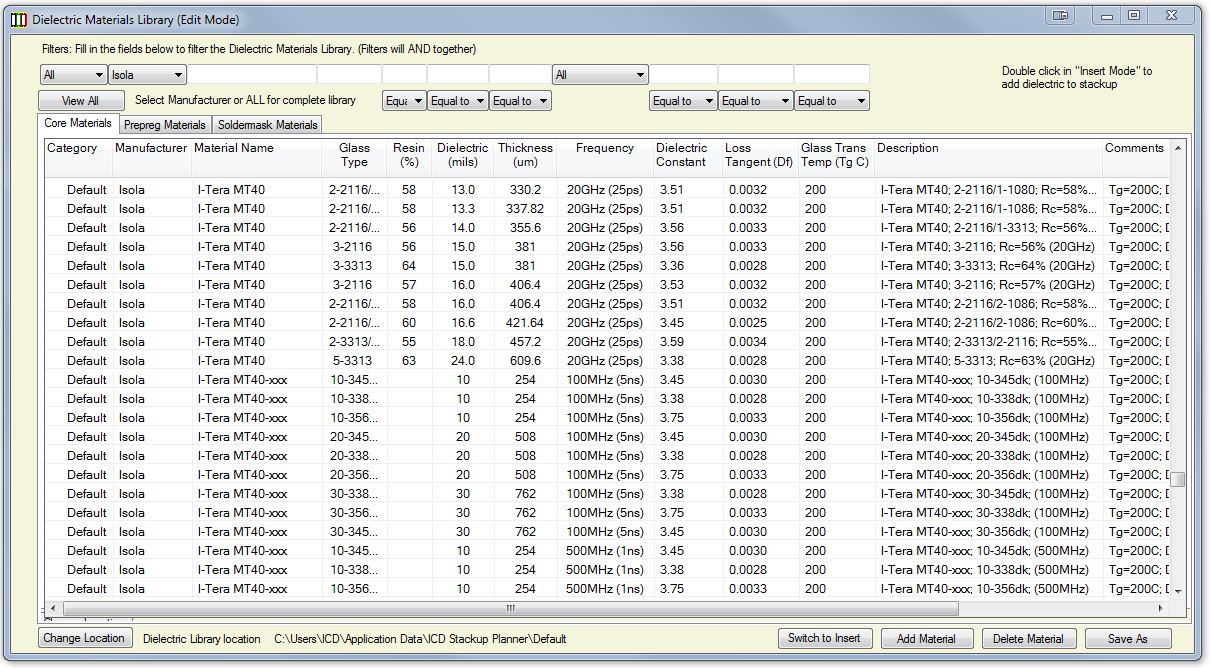

To gain speed, or if no target production location is yet in sight, AQC can also make its own calculations and stack-up proposals. This is done using the iCD Design Integrity / Stackup planner programme. All common impedances can be calculated with it, including Coplanar and broadside coupled impedances. We have the most complete library of common base materials in a broad spectrum: producers, glass types, (copper) thicknesses, frequency ranges and Tg values. Examples of integrated materials: including Isola, Rogers, DuPont, Iteq, Arlon, Ventec, Panasonic, Shengyi , Kingboard etc. iCD Desing Integrety works closely with Allegro, Altium, Excel, HyperLynx, OrCAD, PADS, Zmetrix TDR, and Zuken, among others. AQC has the knowledge to work together with the customer to come up with a good proposal regarding the stackup and the track widths and spacing to be used, using the iCD Design Integrity/Stackup planner.

Do you have any questions or want to make an appointment?Contact us

- info@aqcbv.com Send us an email

- 088-0045500 Reachable from 08.00 to 17.00 hours